Basic Info.

Product Description

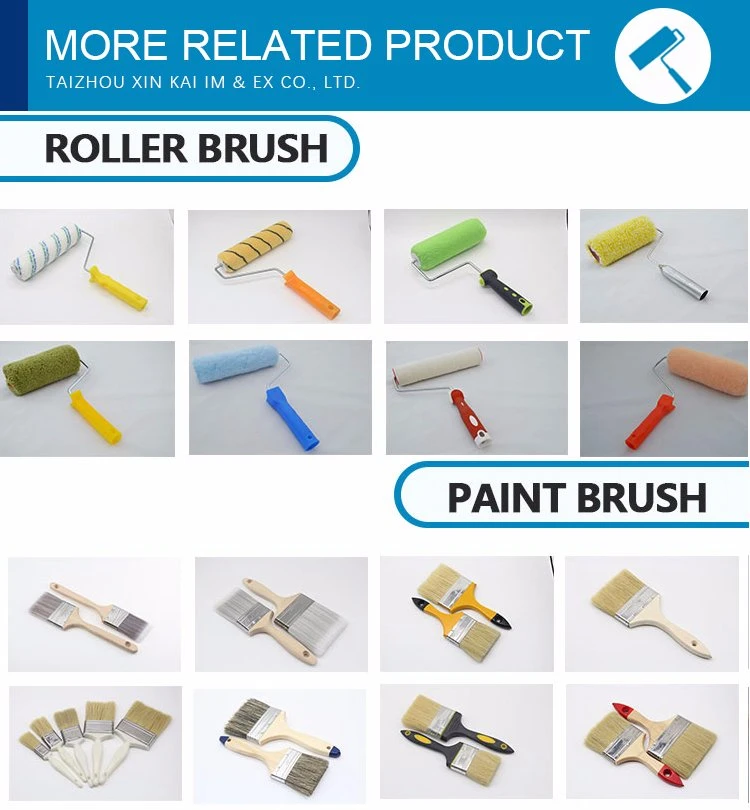

| Roller Brush | |

| Handle Material | PP / PVC / Rubber and Plastic |

| Pile Height | 5mm - 24mm |

| Rebar Diameter | 5.8 / 6 / 6.8 / 7 / 7.8mm |

| Rebar Surface Treatment | Zinc Plating / Chromium Plating |

| Internal Structure | Single Wire, 4 Wire, 5 Wire, Screwed |

| Roller Size | 2, 4, 6, 7, 8, 9, 10 inches |

| Roller Cover Diameter | 38mm, 44mm |

| Roller Cover Material | Polyester, Foam, Microfiber, Polyacrylic, etc. |

| Function | Painting Wall or Building |

| Packing | PP, PE, OPP or Shrink Bags; Corrugated Paper |

Production Process

1, Bristle Production → 2, Hand Shank Molding → 3, Hand Shank Punching → 4, Bristle Production → 5, Hand Shank Molding → 6, Hand Shank Punching → 7, Hand Shank Painting → 8, Tinplate Molding → 9, Fur Attaching → 10, Glue Injection → 11, Combing → 12, Installing Hand Shank → 13, Clipping →14, Packing

Found in 2001, Taizhou Xinkai Group Co., Ltd. is an integration company of industry and trade, mainly specializing in paint brushes, paint rollers and paint tools. Our marketing department is in Taizhou city and factory in Jiangdu city, JiangSu Province. We provided products mainly for trade companies before 2012. Since 2013, we established an import & export company in Taizhou for international business. With the spirit of innovation and creation, we have already won the favor of overseas customers on high quality, vigorous innovation, competitive price and efficient work style.

With a production capacity of 10 million paint brushes and 6 million paint rollers per year, we respond to the increasing demands of the global market quickly. We honor the contract, service clients considerately, deliver the products in time. Now we have build a long-term cooperation with many famous overseas companies and building materials market in America, Canada, Europe, Middle Ease and Southeast Asia Region, etc. Our mission is to be the best OEM partner for global paint tools traders.

We are proud of ourselves in the following aspects:

Low-Cost Manufacturing Base

1.Cost-effective wages and management cost of the plant

2.Own production of the bristle filament, plastic accessories and packages

3.The best use of automatic production methods and handcrafted work

Advanced Technologies

1.Automatic bristles/synthetic filament mixing machines to improve the efficiency

2.Thermo-fusion tech of European roller covers to optimize the product cost

3.Bi-injection machines to make ergonomic brush handles

Reliable Quality Management

1.Specialized workers with years of experience in all phases of the production

2.Rigorous inspections at every step of the manufacturing process

3.Systematical inspection of raw material suppliers to ensure they respect our specifications

FAQ

FAQ

Why chose SINKAI ?

1. Low MOQ (3000PCS) and free samples

2. High standard from raw material to finished products

3. Professional and skilled workers

4. Strict QC department checking every product before packing

5. Long term research on new products and improve present production process

Which payment can we accept ?

1. 30% T/T in advance, 70% balance against the copy of B/L

2. 100% irrevocable L/C at sight

3. Paypay or West Union for small orders

Which logistics ways for shipment?

1. Mostly we'll go by sea for large quantity

2. For these countries near China, we'll go by road or railway

3. For small or sample order, we'll go by DHL, UPS, TNT, FedEx, EMS or another international courier.

Can I trust SINKAI ?

Sure, you can trust us. With us your money in safe and your business in safe!

More than 300+ oversea customers appreciate our quality and service.

Contact us now, know more information about the products you are interested!