Basic Info.

Product Description

2022 Space Saving Ce Approved Touch Lock Clear Float Glass UPVC Sliding Iron Window Grill Color Frame For Office Building

1.Product Introduction

UPVC sliding windows are good water tightness and air tightness.Equipped with multiple sealing weather strips or EPDM sealing strips and rain proof structure, giving full play to air conditioner effect and save 50% energy.

| Style | UPVC Sliding Window | |

| Profile Brand | Chinese Top Brand,1.2mm/1.4mm/2.0mm/3.0mm Wall Thickness | Customized |

| Profile | White Color,Champagne Color Or Wood grain Color | Customized |

| Surface Treatment | Anodizing,Power Coating,PVDF Coating,Electrophoresis,Etc | Customized |

| Glass | Single Or Double Tempered Glass,Laminated Glass,Low-E Glass,Etc | Customized |

| Hardware | German Top Brand 'ROTO' Or Australian 'Doric',Chinese Top Brand | Customized |

| Screen | Retractable Screen,Accordion Screen,Folding Screen,Etc | Customized |

| Rubber Strip | European Standard EPDM | Customized |

| Free Sample | Ready Within 5 Days,Delivery By DHL/TNT | |

| Quality Control | As2047/As2208/Ce/Soccap/Iso9001:2008 | |

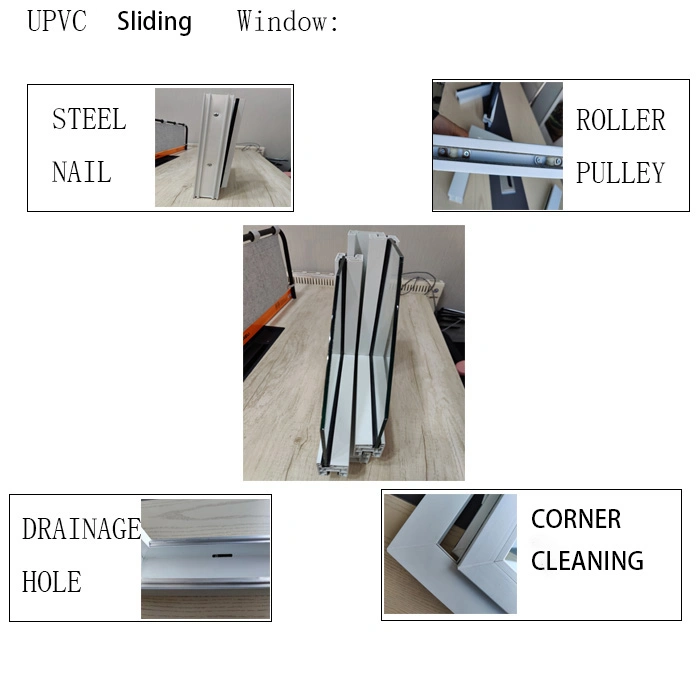

2.Product Detail

UPVC window use polyvinyl chloride (UPVC) resin as the main raw material with a certain amount of stabilizer, colorants, fillers, UV absorbents etc. By extrusion molding, then make into door and window frame sash by cutting, welding or screwing.UPVC window is artistic, sealed, high strength, widely used in buildings like construction, residences, office, commercial office building, commercial center, high-end residence, hospital, laboratory etc.

Glass is an important part of UPVC windows. It has the functions of light transmission, heat insulation, waterproof and windproof. Good glass alsohas the functions of anti-hurricane, dimming and UV protection.

Hardware accessory is also an important part of UPVC windows. Good hardware plays a vital role in the insulation, air tightness and water tightness of doors and windows.Different window types have different hardware options and compositions.

3.Profile Detail

UPVC sliding window profiles series commonly used series are 50/60/70/80/88series,the max-glass-thickness available is 3-24mm,The thickness include 1.6/1.8/2.0/2.2/2.5mm. profiles surface treatments are extrusion profiles,single-sided or double-sided co-extrusion profiles,single-sided or double-sided coated profiles and all-body profile.Color has white and other customized.

4.Glass Details

1.Double tempered glass :5+12A+5,6+12A+6...

2.Single tempered glass:6,8,10,12...

3.Laminated glass:6.38,10.76,10.38...

4.Low-e glass, frosted/obscure glass, grey/blue/green tinted glass...

5.Hardware Accessories

| Hardware | 1: Crescent lock +roller pulley +EPDM sealing strip + wind block + anti-theft block + flynet 2: Touch lock +roller pulley +EPDM sealing strip + wind block + anti-theft block + flynet 3: Hook lock +roller pulley +EPDM sealing strip + wind block + anti-theft block + flynet |

6.Product Parameters

Item | Parameter | Item | Parameter |

K/U (insulation) | <1.1 | Glass thickness/mm | 3-30 |

Airtightness/m3/(m2.h) | ≤0.5 | Profile Width/mm | 50-135 |

Watertighness/Pa | ≥700 | Transmittance | 60%-98% up to glass type |

wind pressure/KPa | ≥5.0 | Fire-proof level | AAAAA |

Profile thickness/mm | 0.8-3.0 | Anti-theft level | AAAAA |

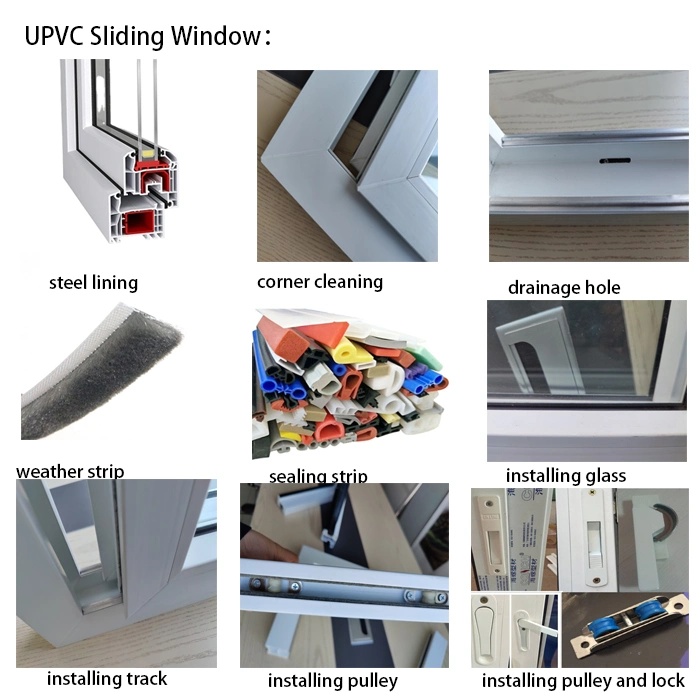

7.Processing Procedure

UPVC sliding window: cutting profile- steel lining - welding angle / corner cleaning - glue - EPDM sealing strip - weather strip - installing glass -installing pulley -installing hardware (crescent lock/ touch lock/hook lock/handle lock,etc.)

8.Quanlity Control

1. Raw material quality testing: the color, thickness and strength of profiles will be checked after the profiles arrive at the factory. After the glass to the factory, the color and thickness of the glass will be checked again, and the sealing performance of hollow glass will be checked. Hardware color will be checked and tests how well the hardware works.

2. In the production process, there will be special quality inspectors to check each process of production.

3. After the product is finished, the group corner, sealing, size, use effect and so on will be tested.

9.Product Package

1. Stretch film packaging

2. 5 carton packaging

3. Fumigation-free wooden frame packaging

4. Packed in wooden cases with fully enclosed and fumigation-free plywood.

Different packing methods can be applied to FCL and LCL.

10.Project Case

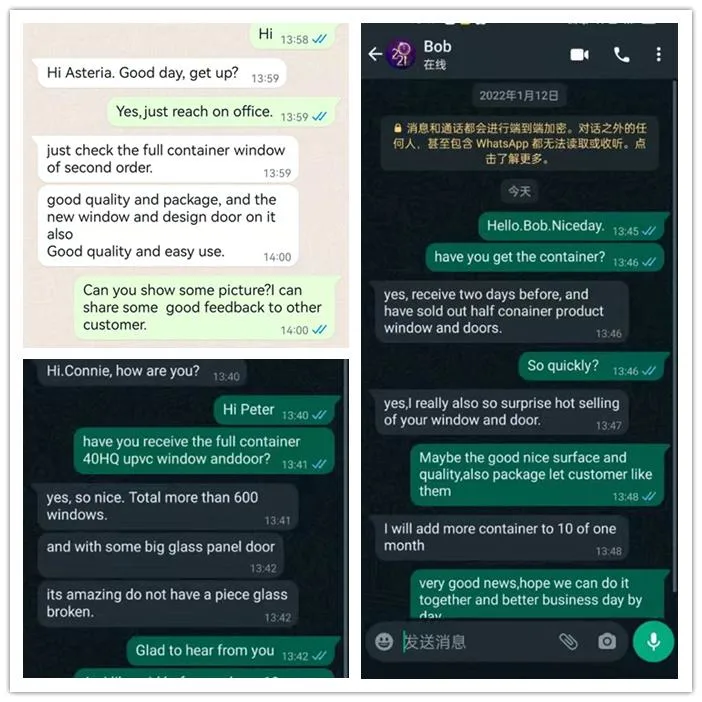

11.Customer Feedback

12.Company Profile

Shandong Super Window House Co., Ltd. is located in Shandong. the production base of doors and windows of China. After 11 years of solid operation, become the good reputation manufacturer of aluminum alloy doors and windows , PVC doors and windows in northern China. It is a Large doors and windows construction engineering enterprise which sets design, production, domestic engineering, export trade, foreign installation in one

13.FAQ

Q1: Are you a factory or trading company?

A: We are Industry and trade integration.

Q2: What is the material of you products?

A: The material is Aluminum or PVC/UPVC profile

Q3: How can I get some samples?

A: We are honored to offer you samples.

Q4: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality controlling from the beginning to the end.

Q5: Are there any problems with the glass inside? Having steam or going foggy? As this will be a real problem.

A: Usually, we use 5mm+9A+5mm double glass, you can be rest assured. Our double glass is made professionally by big factory, no steam or going foggy between the double glass.

Q6:What is the area of your factory?

A:Our factory has three layers and covers an area of 10,000 square meters.

Q7. Is there any price difference between powder coating and anodising?

A. No price difference between them. We recommend you to choose anodised finish if the house is near salt water for long-effective corrosion resistance .but powder coating will be better if the house is far away from salt water.