Basic Info.

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.1mm

Customized

Customized

Delivery

15-20working Days

Experience

Since 2006

Certificate Available

ISO,SGS,Certification of Raw Materials,Normal Cust

Warranty

We Borne 100% Responsibility for Quality Problem

Inspection

100% Factory Inspection in House

Sample

for Free

OEM Experiences

13years

Item

Custom Homemade Metal Stamping Parts

Quality

High Level

Trade Assurance

Protect Your Order Everything

Applied Software

PRO/E,Auto CAD,Solid Work ,Caxa

Sales Team

Response Within 24 Hours

Surface Finished

Sandblasting, Painting, Polishing, Poweder Coating

R&D

3 Engineers for Electric Gold Plated Stamping Part

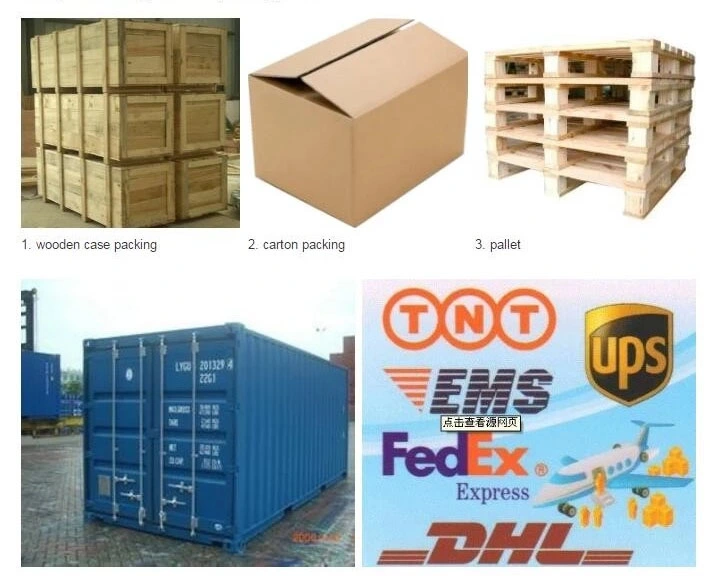

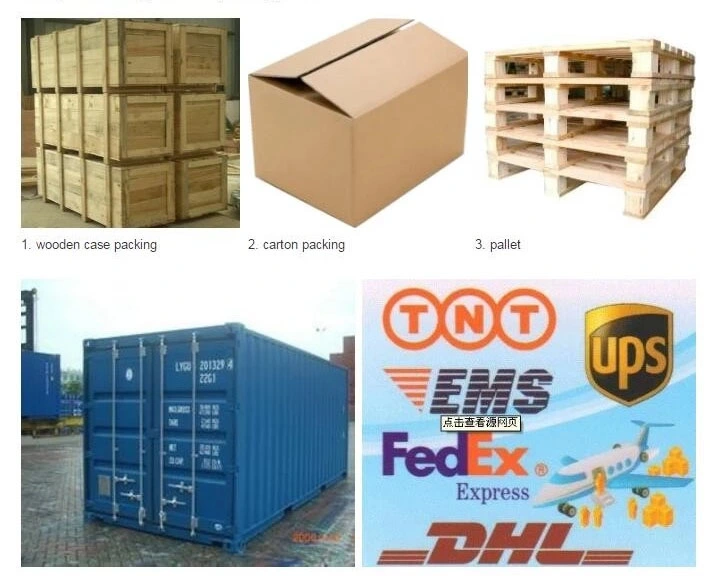

Transport Package

Wooden Box/Cartons/as Your Need

Specification

OEM parts

Trademark

YX

Origin

Shandong, China

HS Code

73261990

Production Capacity

150 Ton/Tons Per Month Custom Stainless Steel

Product Description

Product Description:

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes.It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing, to name a few.

We offer metal stamping services to deliver components for industries in automotive, aerospace, medical, and other markets.As global markets evolve, there is an escalated need for quickly-produced large quantities of complex parts.

Advantage:

Metal stamping is a fast and cost-effective solution for this large-quantity manufacturing need.Manufacturers who need metal parts stamped for a project generally look for three important qualities:

High quality /durability

Low Cost

Fast turnaround time

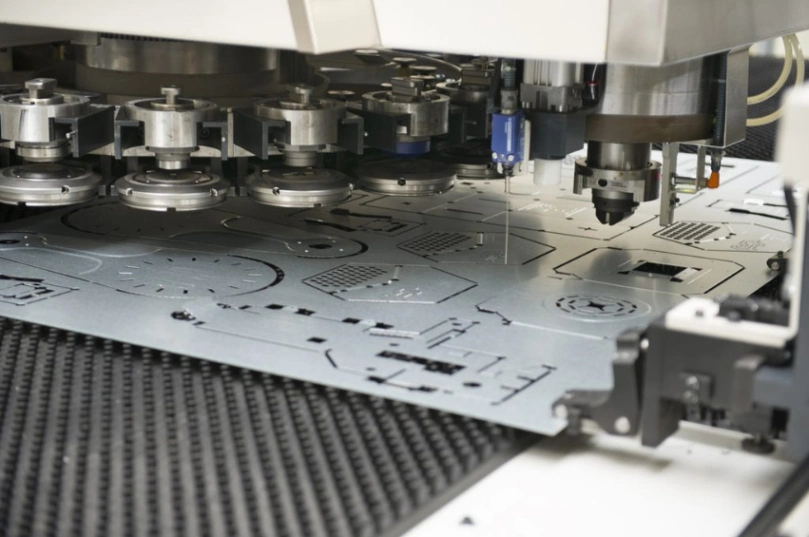

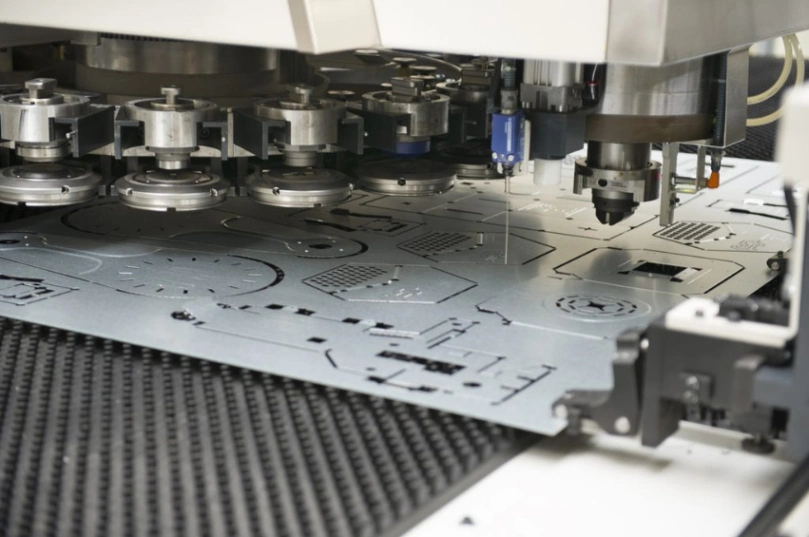

Equipment show:

* Laser cutting: 3 production lines, length 12m , width 3m , thickness 24mm, any shape cutting.

* CNC bending: 6 production lines with a length of 4.1 meters and a pressure of 3200KN, combined with laser cutting for sheet metal production and processing.

* CNC flame cutting: any shape cutting within the range of length 14m , width 2m , thickness 100mm.

* Large gantry milling: Milling in the range of 10 meters in length and 1.5 meters in width.

* Large roller pass type shot blasting equipment: it can finish the surface shot blasting of large workpieces.

* Electrostatic spraying: powder electrostatic spraying

* Large paint oven: paint parts under 10 meters in length.

* Milling machine, lathe, planer, punch, press and other production lines.

Why choices us?

1. auto parts, classic car parts

2. machine parts, pump body housing, engine parts, cylinders, pistons, transmission housing.

3. cookware parts, kitchen ware parts.

4. medical equipment parts, housing, instrument housing, I beam, housing...etc.

5. Bicycle and motocycle parts, sport equipment parts, housings, covers, heat sinks.

Our Policy:

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

"We value Customer Satisfaction"

PACKAGE:

Transport:

SERVICE:

FAQ:

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 14 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Qingdao city and you can get more detailed information by browing our website: http://qdyinxiao.en.made-in-china.com or Visit us in person.

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 3-7 days (automatic machining parts) or 7-10 days (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes.It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing, to name a few.

We offer metal stamping services to deliver components for industries in automotive, aerospace, medical, and other markets.As global markets evolve, there is an escalated need for quickly-produced large quantities of complex parts.

Advantage:

Metal stamping is a fast and cost-effective solution for this large-quantity manufacturing need.Manufacturers who need metal parts stamped for a project generally look for three important qualities:

High quality /durability

Low Cost

Fast turnaround time

Product Specifications: | |

SERVICE | CNC Machining,Sheet Metal Fabrication,Laser Cutting Service,Stamping Parts,Bending,Die casting,Grinding,Spray coating,Printing,Assembing ,etc. |

| MATERIAL | Carbon steel,Mild steel,Cold roll steel,Hot roll steel,Zinc plate,Stainlesssteel,Aluminum,Copper,Brass,Plastic,Die Casting,Silver, Nylon, Cr5, Iron, Nickel plated carbon line,SECC,SGCC,SPCC,SPHC,Other metal |

MAIN MARKETS | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, South Asia, Africa African |

| FINISH SURFACE | Sandblasting, Anodizing Color, Blackenning, Zinc\Nickl Plating, Polishing And Brushing,Zinc plating,Electroplating Nickel plating,Anodic oxidation Chrome plating,Yellow zinc plated Electroless nickel plating Chemical conversion coating Powder coating,Liquid painting |

| MAIN EQUIPMENT | CNC Machining Center(Milling), CNC Lathe, Griantry 3,4 axis CNC Machining Center,Cylindrical Grinder Machine, Drilling Machine, Laser Cutting Machine,Tube Laser Cutting Machine,Flame Cutting Machine,Bending Machine,Stamping Machine,Sand Blasting Machine,Powder Coating Line |

TESTING EQUIPMENT | Coordinate, digital display height ruler, durometer, coating thickness tester,etc. |

| APPLICATIONS | Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment etc |

TOLERANCE | In general:+-0.01-0.05 mm, can be more precision,according to your requirement. |

SURFACE ROUGHNESS | Ra 0.6-3.2 |

DEAWING FORMAT | Step,Stp,Gis,Cad,Pdf,Dwg,Dxf Etc Or Samples. |

| WORKFORCE | A group of experienced production technician, sophisticated engineer and dedicated QC. |

| DELIVERY | Sample: 3~5 days for no mould items and 7~10 days for mould items Mass goods: 15~20 working days.For machining,sample can be finished in 10 days,according to the drawing. |

PAYMENT | T/T, L/C, Money Gram, Western Union |

Equipment show:

* Laser cutting: 3 production lines, length 12m , width 3m , thickness 24mm, any shape cutting.

* CNC bending: 6 production lines with a length of 4.1 meters and a pressure of 3200KN, combined with laser cutting for sheet metal production and processing.

* CNC flame cutting: any shape cutting within the range of length 14m , width 2m , thickness 100mm.

* Large gantry milling: Milling in the range of 10 meters in length and 1.5 meters in width.

* Large roller pass type shot blasting equipment: it can finish the surface shot blasting of large workpieces.

* Electrostatic spraying: powder electrostatic spraying

* Large paint oven: paint parts under 10 meters in length.

* Milling machine, lathe, planer, punch, press and other production lines.

Why choices us?

- In China, we have more than 13 years of experience in processing foreign companies for foreign companies.

- China manufacturer in Qingdao,not trade company

- Competitive price and nice service

- ISO/SGS passed

- Application: Automotive,medical device, electronics, toy, furniture, industrial etc.

1. auto parts, classic car parts

2. machine parts, pump body housing, engine parts, cylinders, pistons, transmission housing.

3. cookware parts, kitchen ware parts.

4. medical equipment parts, housing, instrument housing, I beam, housing...etc.

5. Bicycle and motocycle parts, sport equipment parts, housings, covers, heat sinks.

Our Policy:

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

"We value Customer Satisfaction"

PACKAGE:

Transport:

SERVICE:

FAQ:

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 14 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Qingdao city and you can get more detailed information by browing our website: http://qdyinxiao.en.made-in-china.com or Visit us in person.

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 3-7 days (automatic machining parts) or 7-10 days (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.