- Overview

- Product Description

- Detailed Photos

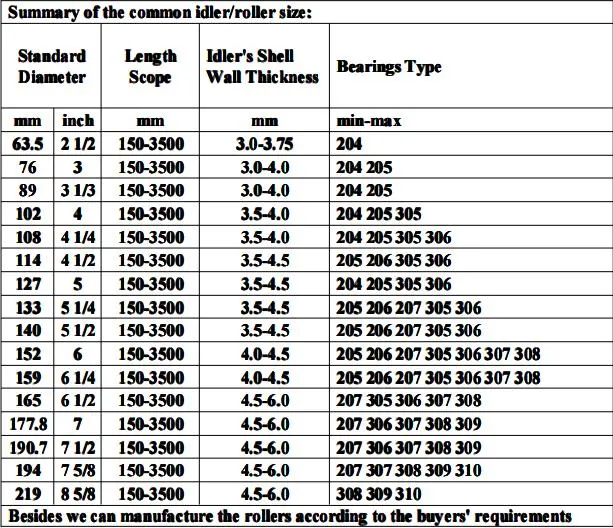

- Product Parameters

- Packaging & Shipping

- Certifications

- Application

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Shaft is high precision cold steel, Tube is high frequency seam welding, Decrease diameter runout and To ensure the operation process uniform rotation.Bearing use for HRB,ZWZ,LYC, bearing seat and dust cup use for high quality steel pressing, Lubrication using disposable high efficiency and long lithium base, And the labyrinth seal structure, waterproof, dustproof performance is good.

Roller load coefficient according to CEMA standard selection; Roller bearing with choose according to DIN standard;

Conveyor roller advantages:

1.Small Radial runout,weighting roller is below 0.35mm

2.Small rotating resistant,the resistant coefficient is below 0.010

3.Under testing of 72-hours water poof,water inflow is zero.

4.Permanent lubrication,long service life(at least 30,000 hours)

We have ISO9001,CE, ISO18001 and ISO14001 certificated. Our company manufactures many kinds of Roller, frame, pulley and conveyor steel structure. We can design and manufacture based on clients' drawings&requirements.

1. With corrosion resistance.

2. Strong hardness: strong abrasion resistance.

3. Good tightness.

4. Smooth surface without material.

5. Grooved rollers use 2-5 times longer than steel rollers and reduce belt wear.

6. Low operating costs: Reduce the overall cost of belt conveyors and reduce maintenance hours.

We can make gravity conveyor roller,steel conveyor roller,tapered roller,impact roller,nylon roller,HDPE roller, rubber coated roller,rubber coating roller,screw roller and other conveyor rollers.

| Diameter | 60-219mm |

| Length | 100-3500mm |

| Tube | Q235(GB) |

| Shaft | 45# steel(GB) equal to C45 |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RZ&2Z wigh C3 clearance |

| Grease | Lithium soap type grease,grease retaining inner seal with Multi-stage Labyrinth and Retention Cap with Outboard Rubbing Flinger Seal |

| Lubrication | Grease is Lithium soap type grease with Rust Inhibitors |

| Welding | Mixed gas shielded arc welding end |

Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

Our company is the High-end Conveying Equipment brand , with excellent technical team and in house intellectual property & national patents,developing intelligent conveying machinery. Focusing on transforming itself into international competitive one-station solution provider of intelligent conveying system, providing not only intelligent products but also whole cycle management from construction to operation & service for our customers.our company is mainly engaged in the manufacture, sales and technical services of belt conveyors, large angle belt conveyors, horizontal curved belt conveyors and long distance crossing conveyors. Our products can be used in metallurgy, building materials, electric power, coal, port and other industries, products have been covered the whole domestic market, and exported to the United States, Germany, France and other EU countries, Australia, Brazil, along the Belt and Road countries, Southeast Asian countries and African emerging markets, totally more than 50 countries, gained the customers' praise.

Q1. Are you a manufacturer?

A. Yes, we have been producing and selling conveyor rollers for 19 years.

Q2. Can you produce conveyorroller as my requirements?

A. Yes, we can.

Q3. What about the lead time?

A. 1) 5~7 days for sample (free sample)

2) 15~30 days according to order quantity

Q4. How about payment terms?

A. 1) We prefer T/T, 30% advance paid upon order, rest upon b/l copy, or

2) Sight or deferred L/C, or

3) Other payment terms approved.

Q5. How do you ensure product quality?

A. 1) We have a R&D center of an independent design and developing capacity

2) We an independent testing laboratory with full-property testing capacity of conveyor roller