- Overview

- Product Description

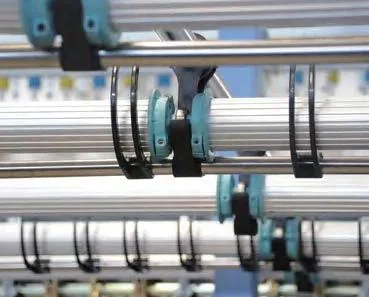

- Details Showing

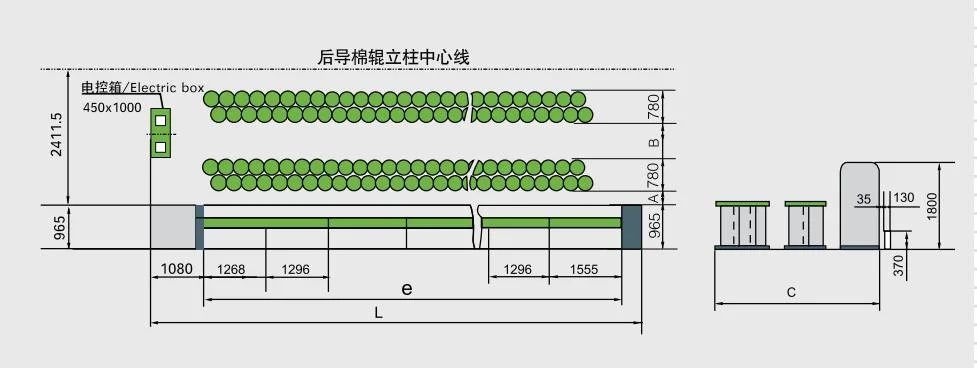

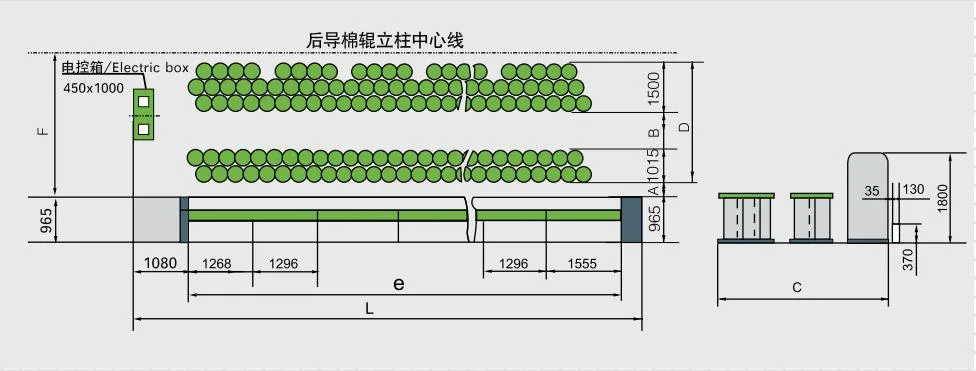

- Product Parameters

- Company Profile

Basic Info.

Product Description

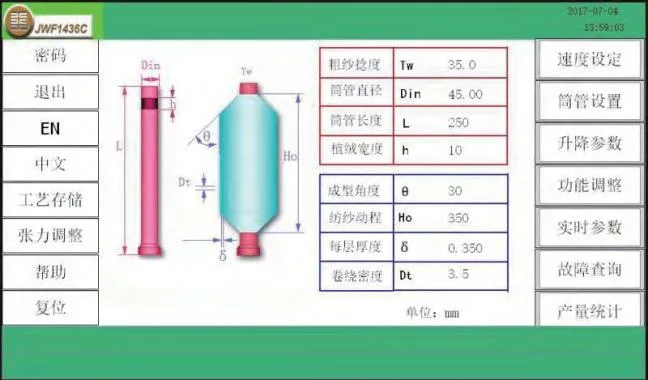

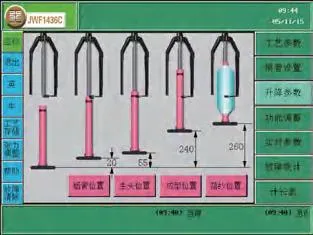

Model JWF1436C,JWF1446C Roving Frame is the latest generation cone drumlessversionwhich is developed on the base of FA series with the microcomputer control.The regulating speed by inverter.The machine has the high level of mechanical and electrical integration.High-precision control system and in the form of four motor divisions drive, so that the whole of spinning process to achieve a digital control,with high yarn quality and high reliability.

1- HIGH SPEED

Using high-speed closed type flyer, by gear transmission.

2- HIGH EFFICIENCY AND SIMPLE OPERATION

All process data is stored and can be recalled up at any time.Except the drafting changegears,all of other change gears are eliminated.parameters are input directly on the touch screen.The technological parametrs are input directly on the touch screen.

3- PURSUITTHE HIGH QUALITY ROVING

The current inspecting and feedback controlling system are composed of CPU and multi rotary encoderswith high accuracy.

The digitallsation control is accomplished by the inverter control system with high accuracy. The rovingtension is strictly controlled during running by math. patterns to ensure the uniform roving tension.

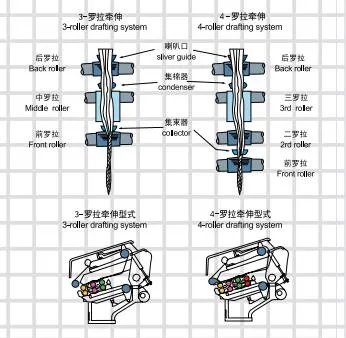

3-roller and 4-roller double short aprons drafting system are available at option.

STANDARD CONFIGURATION:

Chinese YJ-40 Spring-loaded pendulum arme.OPTIONAL CONFIGURATION:

The pendulum arm of Texparts PK1550 and Roller bearing;Suessen Leaf spring pressure pendulum arme and Roller bearing.

The perfect self-cleaning system is presented in this machine. Upper and bottompositive intermittent revolving cloth are adopted and the traveling cleaner andsuction channel are equipped.The waste combed from the bottom clearer cloth together with the flyingsaccumulated on spindle rail cover and roller beam are all blown into the suctionoutlets which are located on the back side of roller beam .Meanwhile the wastecombed from the upper clearer cloth is suck up by the traveling suction nozzle,foreffective preventing the flyings to adhere into the roving and decreasing the rovingfaults.

The guide roller is made of the aluminium alloy with the positive feeding.The closed type ball bearings are equipped with the connecting places ofthe guide roller of each staff to eliminate the false draft.

CAN FOR φ16# INCH

CAN FOR φ20# INCH

| 1 | Quantity | jwf1436c sets |

| 2 | No.of Spindle | 24 24Sspindles/frame |

| 3 | Fiber Length | 22-38mm;65mm cotton fiber 22-38 mm; chemical fiber below 65mm |

| 4 | (Tex) Adoptable Count (Tex) | 200-1000 |

| 5 | Mechanical Speed | 1200/ 1200 rpm |

| 6 | Spindle Gauge | 216mm |

| 7 | Full Package | 152 x 400 mm |

| 8 | Flyer | fully enclosed type |

| 9 | Creel | 6φ500 x 1100 row creel suitable for can size Φ500 x 1100 mm |

| 10 | Draft Range | 4.2 - 12 4.2 - 12 times |

| 11 | Twist | 18.5 - 80/ 18.5 - 80 T/m |

| 12 | DRAFTING | TEXParts PK 1550 EU SAUER TEXPARTS PK 1550 (4 X 4) ROLLERS PENDULUM ARMS, ROLLERS, CRADLE OH514-6962746 DISTANCE CLIPS, PRESS FIT RUBBER COTS (SHORE HARDNESS 82 DEGREE) |

| 13 | Bottom Roller | 28 x 28 x 28 x 28 mm() 28 x 28 x 28 (knurled) x 28 mm |

| 14 | Infrared Photocell | 5, 5 pairs, China |

| 15 | Main bearing of head stock | Germany |

| 16 | Motor Power | 380V,400V,415V±10% 50Hz, |

| 17 | Main Motor with inverter | 11kw for flyer |

| 18 | Winding Motor: | 11kw(120S),15kw(156S) 11kw(120S) for bobbin,15kw(156S) for bobbin |

| 19 | Roller Motor | 4KW(120S),5.5KW(156S) 4KW(120S)for roller,5.5KW(156S)for roller |

| 20 | Lifting Motor: | 1.5kw 1.5kw for bobbin rail lift |

| 21 | Motor for blowing | 4KW |

| 22 | Motor for overhead cleaner | 1.5kw |

| 23 | Dimension (L x W) | 4407×4100(24,Φ500 x 1100 mm) 4407×4100mm(for24 spindles, Φ500 x 1100 mm) |

| 24 | Overhead Cleaner | one for one machine |

| 25 | Total rated power | 33KW(120S),38.5KW(156S) 33kw(24S),(including the travelling cleaner) |

Qingdao Hongda Textile Machinery Co., Ltd (here after referred to as QDHD)is the subsidiary company ofJingwei Textile Machinery Co. Ltd. It is a large-scale backbone enterprise of textile machinery manufacture,as well as an important manufacturing base for carding machinery and auto-winder.

The Technology Center of QDHD is certified as the National Technology Center. Blowing-Cardingmachinery wins the First-Class Scientific and Technological Progress Award issued by China Textile IndustryAssociation and is the promotion program in The Ninth Five-Year Plan of the State Science and TechnologyCommission. The three leading products of QDHD-Carding Machine, Blowing-Carding Machine and Auto-winder, have all passed the ISO9001 quality system authentication, winning QDHD the honor of "PioneerEnterprise of National Quality Control".

Facing the new situation, Qingdao Hongda Textile Machinery Co. Ltd will be committed to continuouscontribution to the development of Chinese textile machinery, the technological progress of the Chinesetextile industry and the improvement of its international competitiveness by executing new initiatives andadvancing with times.